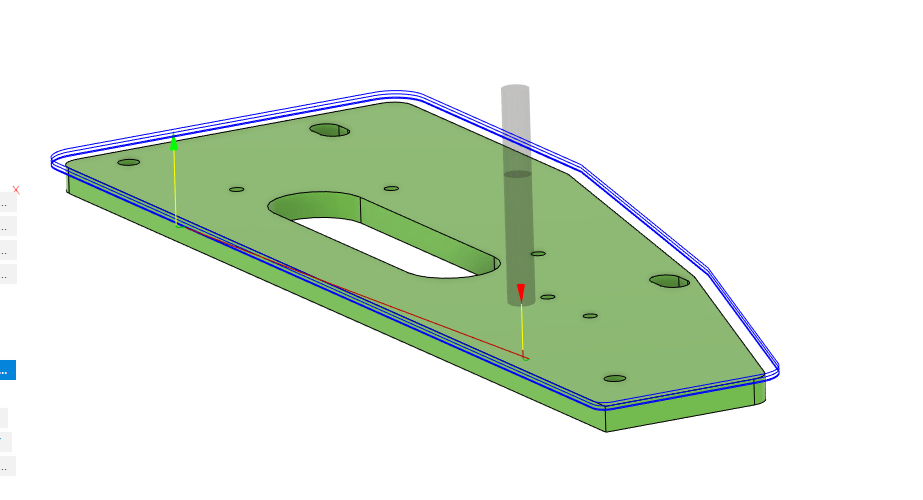

I do not have a vacuum setup and I came across a .239 part that was about 4 inches wide and 10 inches long, but essentially missing one corner, pretty much like this:

Op 1 was done in a vise with talon grips. For op 2 I milled a set of soft jaw that would use the geometry to my advantage. However, there was a thin sheet of about .08 floating in space. I had a feeling that a typical facing op would not work but since it was only qty 1 I gave it a try.

I went with a 1/4″ rougher to lower all forces with a smaller stepover, but when the material began to ribbon and vibrate, it interfered with the cutter and lifted the part. Fail!

I was happy enough with the work holding and I figured that if I could just get that excess material out of the way I would be good. The solution I came up with had me contour the part starting at the stock top and ramping down at a 2 degree angle. I went light on the DOC, about half the remaining stock (.050″) and it worked like a charm. I ended up with just material above the part, nothing floating.

After this I still went light, still using the 1/4″ to reduce forces and took two passes on the remaining Z stock. Once I was down to my last .005, I went with my normal facing toolpath.